Factories face growing pressure to control energy costs, maintain reliable production, and reduce carbon emissions. Combined Heat and Power (CHP) systems offer a highly efficient solution by generating electricity and useful heat from a single fuel source, significantly reducing energy waste.

For manufacturing facilities with continuous or high energy demand, CHP is not just an energy upgrade; it is a long-term operational advantage.

At CHP System, we design and deliver CHP solutions specifically for factories, helping manufacturers lower costs, improve efficiency, and support sustainability goals.

What Is CHP and Why Does It Work So Well in Factories

Traditional energy supply is inherently inefficient. Electricity is produced at remote power stations where large amounts of energy are lost as heat, then transmitted across the grid before reaching your site. Heat is generated separately using boilers, requiring additional fuel and increasing costs.

A CHP system produces electricity on-site and captures the heat created during generation. Instead of being wasted, this heat is reused for manufacturing processes, space heating, hot water, or steam. By using both outputs from the same fuel input, CHP systems can achieve total efficiencies of up to 80–90%.

To put this into perspective, from every 100 units of fuel, a CHP system can typically deliver around 40 units of electricity and up to 45 units of usable heat. Achieving the same output using grid electricity and conventional boilers would require significantly more fuel, leading to higher energy bills and increased emissions.

Lower Energy Costs and Improved Cost Control

Energy is a major operational expense for factories, particularly those running multiple shifts or energy-intensive processes. CHP systems reduce energy costs by generating electricity at a lower cost than the grid supply while simultaneously reducing the need for boiler fuel.

Because power is produced on-site, factories also gain greater control over their energy spend. CHP reduces exposure to rising electricity prices and helps stabilise long-term operating costs, making budgeting more predictable.

Over the lifetime of the system, these savings often outweigh the higher initial investment when compared to traditional energy solutions.

Greater Energy Efficiency and Operational Reliability

Factories are ideal environments for CHP because they typically have consistent heat and power demand. CHP systems perform best when operating continuously at high load, which aligns perfectly with manufacturing schedules.

On-site generation reduces reliance on the national grid, improving resilience and reducing the risk of disruption. For production environments where downtime is costly, the ability to maintain a stable power and heat supply is a significant advantage.

Reducing Carbon Emissions in Manufacturing

CHP systems reduce carbon emissions by making better use of fuel and eliminating the losses associated with electricity transmission. By extracting more usable energy from each unit of fuel, factories can significantly reduce their overall carbon footprint.

This makes CHP an effective tool for meeting environmental regulations, corporate sustainability targets, and net-zero commitments. For manufacturers under pressure to decarbonise without compromising productivity, CHP provides a useful and proven pathway.

Correct CHP Sizing: An Important Success Factor

The performance of a CHP system depends heavily on correct sizing. Systems that are too large may operate inefficiently, while undersized units fail to deliver the full financial and environmental benefits.

At CHP System, CHP units for factories are sized based on detailed analysis of heat demand, electrical load profiles, operating hours, and future production plans. When heat and electricity demand are well matched, CHP delivers maximum efficiency, reduced fuel consumption, and the strongest return on investment.

CHP vs Conventional Boilers: A Smarter Long-Term Choice

Conventional energy systems require factories to burn fuel solely for heat while purchasing all electricity separately from the grid. This approach results in higher fuel consumption and greater long-term costs.

CHP changes this model by producing heat and electricity simultaneously from the same fuel input. The result is lower overall energy use, reduced operating costs, and improved energy performance across the site.

While CHP systems may require higher upfront investment, they consistently deliver superior value over their operational lifetime.

Future-Ready CHP for the Energy Transition

CHP technology continues to evolve alongside the wider energy transition. Modern systems can be designed to operate on a range of fuels, including:

- Natural gas

- Biogas

- LPG

- Hydrogen blends, with future capability for 100% hydrogen

At CHP System, we deliver future-ready CHP installations that protect your investment while supporting long-term decarbonisation strategies.

Why Factories Choose CHP System

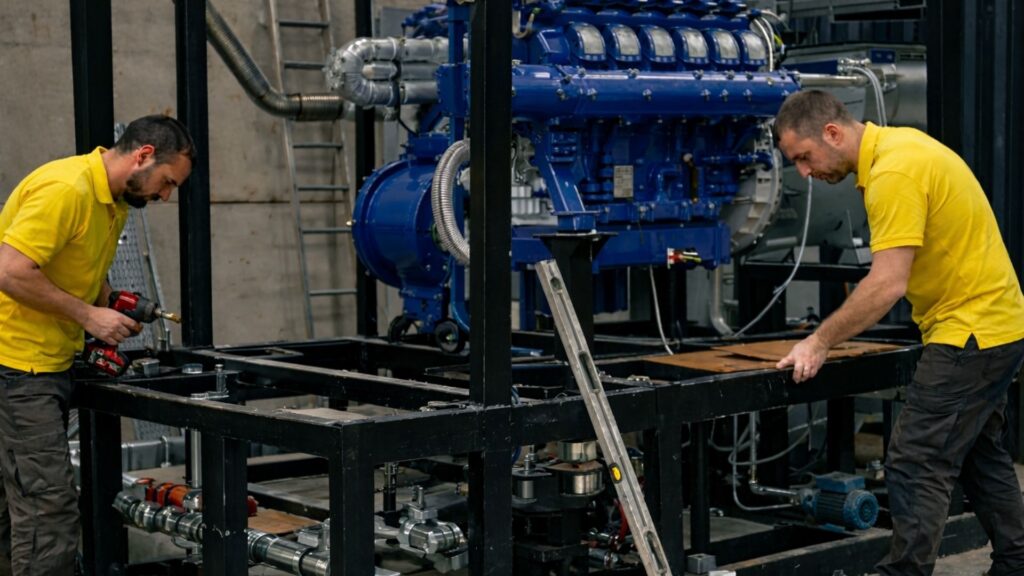

Selecting the right CHP partner is essential to achieving reliable performance and long-term savings. CHP System provides expert design, installation, and maintenance services tailored to industrial environments.

With proven experience across manufacturing sectors, we deliver precisely engineered CHP systems supported by full lifecycle service from feasibility and installation through to ongoing maintenance and optimisation.

Book a CHP Consultation for Your Factory

Whether you are assessing CHP for the first time or upgrading an existing energy system, our specialists are ready to support you.

By booking a consultation with CHP System, you can identify potential energy savings, understand your carbon reduction opportunities, and receive a CHP solution tailored to your factory’s operational needs.

Book your CHP service today and take the first step towards lower energy costs, improved efficiency, and a more sustainable manufacturing future.